Honey being a biological substance and intended for food & pharmaceutical use needs greater attention in quality and its handling. The moisture content in honey plays an important role in deciding the quality of honey. Honey with more than 20% moisture are thinner in consistency. The moisture content in honey increases due to hygroscopic nature of honey in which the surrounding atmospheric moisture is absorbed by honey. If the moisture content is more than 20% the honey is liable to spoilage due to fermentation & granulation. Considering the present practice of collection, storage & handling of honey under uncontrolled conditions including climatic factors the honey needs processing, reduction of moisture & packing by utmost care to protect the valuable natural properties.

Honey being a biological substance and intended for food & pharmaceutical use needs greater attention in quality and its handling. The moisture content in honey plays an important role in deciding the quality of honey. Honey with more than 20% moisture are thinner in consistency. The moisture content in honey increases due to hygroscopic nature of honey in which the surrounding atmospheric moisture is absorbed by honey. If the moisture content is more than 20% the honey is liable to spoilage due to fermentation & granulation. Considering the present practice of collection, storage & handling of honey under uncontrolled conditions including climatic factors the honey needs processing, reduction of moisture & packing by utmost care to protect the valuable natural properties.

COMPOSITION

| Water (Moisture) |

- |

20% |

| Fructose (Levulose) |

- |

37% |

| Glucose (Dextrose) |

- |

34% |

| Sucrose (Non Reducing Sugar) |

- |

5.0% |

| Total Ash (Minerals) |

- |

0.25% |

| Acids Organic |

- |

0.20% |

| Proteins, Amino Acids, etc. |

- |

1.50% |

| Other ingredients including pollen

grains |

- |

1.05% |

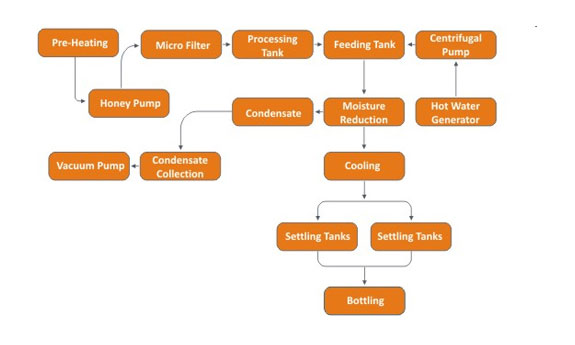

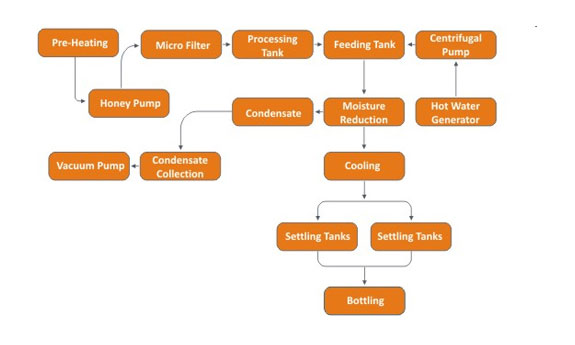

BRIEF PROCESS DESCRIPTION

- Liquification

- Pre-Heating and Straining

- Micro-filtration

- Inactivation of Yeast Cells (Processing)

- Vacuum Evaporation

- Cooling of Honey

HONEY EXTRACTION PROCESS

Eggs are an excellent food containing many essential nutrients. The higher nutrients density of eggs relative to their calorie content makes them excellent food. Two large chicken eggs contains about 12 gms of protein, 1.2 gms of carbohydrate 11 gms of lipids and substantial amount of iron, phosphorous, vitamin A, E, K and most of the B complex vitamins. White portion of the egg contains almost 90% water, but contributes about 50% protein, niacin and riboflavin. Most of the vitamins and minerals are found in egg yolk. The yellow color of egg yolk is due to the presence of xanthophylls pigment.

Eggs are an excellent food containing many essential nutrients. The higher nutrients density of eggs relative to their calorie content makes them excellent food. Two large chicken eggs contains about 12 gms of protein, 1.2 gms of carbohydrate 11 gms of lipids and substantial amount of iron, phosphorous, vitamin A, E, K and most of the B complex vitamins. White portion of the egg contains almost 90% water, but contributes about 50% protein, niacin and riboflavin. Most of the vitamins and minerals are found in egg yolk. The yellow color of egg yolk is due to the presence of xanthophylls pigment.

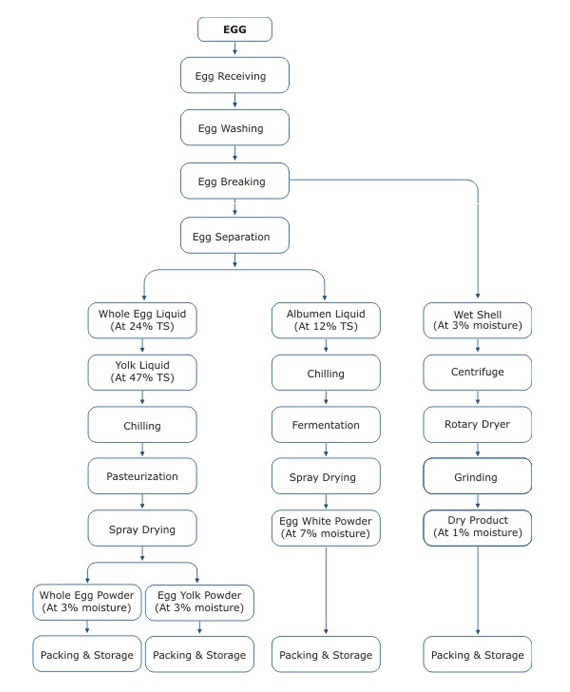

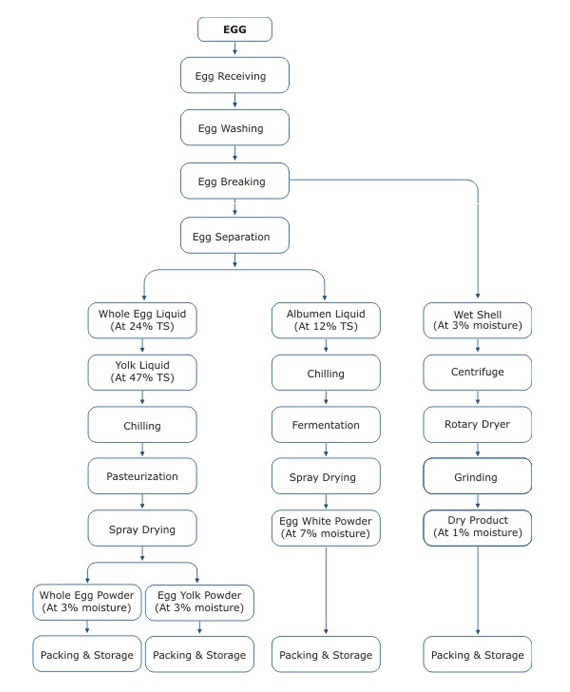

PROCESS:

Eggs are taken from the cold storage and weighed. Dirty eggs are sent to a washing machine before they are broken. Rotten eggs are removed by candling. Egg breaking can be done manually or by using continuous egg breaking & separation machines. A skilled operator can break 500 to 800 eggs per hour. In case of large handling fully automatic machines are available.

For processing egg whites, efficient separation of egg whites from yolks is of great importance as no yolk must contaminate the whites. Even a small amount of yolk oil in albumen greatly reduces the quality of the product. Modern machines can achieve the limits of yolk oil in egg white to the extent of < 0.02%, which is acceptable.

In the production process of whole-egg or egg-yolk powder, whole eggs/egg yolks are homogenized, filtered to remove membranes and fragments of shell pieces. Pasteurization will be done at 64 to 66°C, with a holding time of 2 to 4 min. This ensures inactivation of most of the microbes such as E. coli and Salmonella which can cause ill health, if not inactivation.

After pasteurization whole eggs (solids content 20 to 27%) or egg yolk (solids content 40 to 48%) are fed to the spray dryer. The drying-air inlet temperature ranges between 150°C and 200°C. Final powder has a moisture content of 2 to 4% and bulk density of 0.3 0.35 g/cm³. The powder is then packed suitably after subsequent cooling.

FLOW DIAGRAM OF EGG PROCESSING PLANT

Honey Processing Plant

Honey Processing Plant  Honey being a biological substance and intended for food & pharmaceutical use needs greater attention in quality and its handling. The moisture content in honey plays an important role in deciding the quality of honey. Honey with more than 20% moisture are thinner in consistency. The moisture content in honey increases due to hygroscopic nature of honey in which the surrounding atmospheric moisture is absorbed by honey. If the moisture content is more than 20% the honey is liable to spoilage due to fermentation & granulation. Considering the present practice of collection, storage & handling of honey under uncontrolled conditions including climatic factors the honey needs processing, reduction of moisture & packing by utmost care to protect the valuable natural properties.

Honey being a biological substance and intended for food & pharmaceutical use needs greater attention in quality and its handling. The moisture content in honey plays an important role in deciding the quality of honey. Honey with more than 20% moisture are thinner in consistency. The moisture content in honey increases due to hygroscopic nature of honey in which the surrounding atmospheric moisture is absorbed by honey. If the moisture content is more than 20% the honey is liable to spoilage due to fermentation & granulation. Considering the present practice of collection, storage & handling of honey under uncontrolled conditions including climatic factors the honey needs processing, reduction of moisture & packing by utmost care to protect the valuable natural properties.

Eggs are an excellent food containing many essential nutrients. The higher nutrients density of eggs relative to their calorie content makes them excellent food. Two large chicken eggs contains about 12 gms of protein, 1.2 gms of carbohydrate 11 gms of lipids and substantial amount of iron, phosphorous, vitamin A, E, K and most of the B complex vitamins. White portion of the egg contains almost 90% water, but contributes about 50% protein, niacin and riboflavin. Most of the vitamins and minerals are found in egg yolk. The yellow color of egg yolk is due to the presence of xanthophylls pigment.

Eggs are an excellent food containing many essential nutrients. The higher nutrients density of eggs relative to their calorie content makes them excellent food. Two large chicken eggs contains about 12 gms of protein, 1.2 gms of carbohydrate 11 gms of lipids and substantial amount of iron, phosphorous, vitamin A, E, K and most of the B complex vitamins. White portion of the egg contains almost 90% water, but contributes about 50% protein, niacin and riboflavin. Most of the vitamins and minerals are found in egg yolk. The yellow color of egg yolk is due to the presence of xanthophylls pigment.